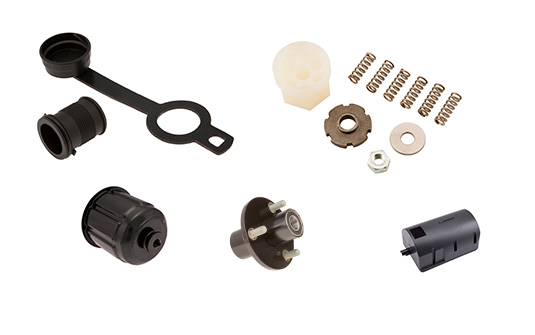

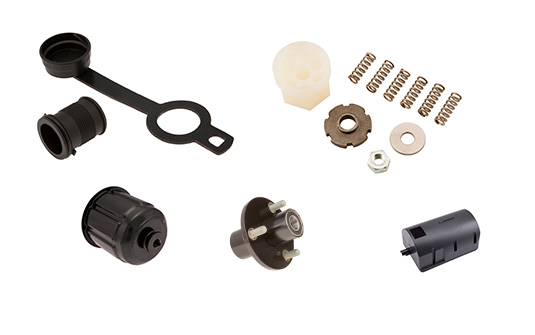

OEM Equipment Parts: Making Sure Ideal Performance and Longevity

OEM Equipment Parts: Making Sure Ideal Performance and Longevity

Blog Article

Making Best Use Of the Worth of Your Investment With High-Quality OEM Building And Construction Parts

In the world of building and construction projects, the selection of using initial devices manufacturer (OEM) parts can not be overemphasized. The adherence to premium OEM building and construction parts holds the vital to unlocking a myriad of advantages that straight affect the long life and performance of your investments. From making sure seamless compatibility to ensuring optimum performance, OEM parts play an essential duty in protecting the integrity of your building and construction ventures. By diving into the realm of OEM components, one can witness direct how this critical choice not only promotes quality requirements yet also paves the method for a affordable and sustainable technique to construction projects.

The Importance of OEM Parts

Using original equipment producer (OEM) parts in construction projects is crucial for ensuring optimal performance, integrity, and longevity of the equipment and devices entailed. OEM components are specifically created and engineered to meet the exact specs of the devices, guaranteeing seamless assimilation and compatibility (OEM Equipment Parts). By making use of OEM components, construction firms can minimize the risk of malfunctions, failures, and pricey repair services that may result from using aftermarket or common components

One of the key benefits of OEM parts is their top quality and consistency. Producers generate OEM components to the same criteria as the original components, assuring a degree of performance that might not be attainable with alternative components. Additionally, OEM components typically come with service warranties, offering construction business with added comfort and defense against failings or problems.

Furthermore, utilizing OEM parts can help preserve the resale worth of construction devices (OEM Equipment Parts). Buyers often favor machinery that has actually been outfitted with authentic OEM components, as they are seen as a mark of top quality and reliability. Inevitably, buying OEM parts can bring about enhanced efficiency, decreased downtime, and total cost savings over time

Advantages of Making Use Of OEM Parts

Furthermore, OEM parts frequently feature guarantees, supplying comfort to construction task supervisors and owners. These service warranties can cover defects or mistakes, supplying security versus unanticipated expenses associated with part failings. By utilizing OEM components, building specialists can additionally maintain the integrity of their devices. Since OEM components are made to fulfill the precise specifications of the original components, they aid preserve the overall efficiency and safety and security standards of the machinery.

Cost-Efficiency of OEM Components

Having actually developed the benefits of using OEM parts in building and construction projects, a crucial facet to take into consideration is the cost-efficiency associated with these genuine elements. While OEM components might have a slightly greater upfront cost compared to aftermarket options, their long-term cost-efficiency is undeniable. OEM parts are developed to fit flawlessly with the existing machinery, decreasing the need for alterations or modifications that can incur extra expenditures. Moreover, the excellent quality of OEM components makes certain a longer lifespan and far better efficiency, eventually causing reduced upkeep and replacement costs with time.

On top of that, making use of OEM parts can aid protect against unanticipated downtime as discover this a result of devices failing. Real parts are produced to meet the precise requirements of the original devices, lowering the danger of malfunctions and break downs that can stop building and construction tasks and result in expensive hold-ups. By purchasing OEM components, building and construction companies can make sure smooth procedures, enhanced productivity, and inevitably, higher cost-efficiency in the long run.

Quality Control With OEM Parts

Guaranteeing excellent quality requirements, OEM components use building and construction projects unmatched integrity and performance. Quality guarantee with OEM parts is an important aspect that sets them apart from aftermarket choices. Original Tools Maker parts go through extensive screening and must satisfy rigorous requirements set by producers. This guarantees that each element satisfies the required specifications, giving a degree of consistency that is important for building and construction tasks.

One key benefit of OEM parts is the assurance of compatibility and fit. OEM Equipment Parts. By utilizing OEM components, construction teams can be certain that each piece will seamlessly integrate with the existing tools, minimizing the danger of delays or malfunctions because of incompatible components. This compatibility not only conserves time throughout the building process yet additionally adds to the total efficiency and safety and security of the project

In addition, OEM components commonly feature service warranties that further underline their high quality and dependability. These warranties offer included assurance to task managers and professionals, understanding that they are purchasing elements that are backed by the maker's guarantee of efficiency. Overall, the quality control provided by OEM parts is a crucial consider making the most of the worth and durability of building investments.

Long-Term Worth of OEM Parts

With a concentrate on longevity and sustained efficiency, OEM components use building jobs a reputable and economical solution for keeping functional effectiveness over extended durations. Selecting OEM components makes certain that equipment operates at peak efficiency levels, reducing the danger of unanticipated malfunctions or malfunctions that can create expensive hold-ups. By buying top notch OEM parts, construction business can reduce the requirement for frequent substitutes and fixings, inevitably resulting in substantial cost savings in the lengthy run.

Conclusion

Finally, utilizing top notch OEM construction components is vital for optimizing the value of your investment. OEM components provide various benefits, including cost-efficiency, quality control, and long-term worth. By selecting OEM parts, you can make certain that your building and construction project is developed to the highest possible standards and will remain to carry out at ideal levels for many years to find.

Using original tools producer (OEM) parts in building jobs is necessary for guaranteeing optimum performance, dependability, and long life of the machinery and equipment included. By utilizing OEM components, construction companies can reduce the danger of Read More Here malfunctions, breakdowns, and costly repair work that may result from the use of aftermarket or common parts.

Suppliers generate OEM click to read components to the exact same requirements as the initial parts, ensuring a degree of performance that may not be achievable with different components. OEM components, which are made by the original tools producer, use an array of advantages that straight affect the effectiveness, efficiency, and durability of building equipment. By using OEM parts, building and construction teams can be confident that each item will seamlessly integrate with the existing tools, minimizing the threat of breakdowns or delays due to inappropriate components.

Report this page